Understanding Varnish in Gas Turbines

Causes, Effects, and Mitigation Strategies for Varnish Issues

Gas turbines are critical to power generation, industrial processes, and aviation. One of the most persistent maintenance challenges is varnish formation in the lubrication and hydraulic systems. Varnish can trigger serious operational issues and unplanned outages, undermining reliability and efficiency. This post explains what varnish is, how it forms, why it matters, and practical steps to monitor, control, and prevent it.

Figure 1: MPC from a General Electric Frame 7. Elevated levels of varnish may lead to valve stiction causing an unexpected and costly outage.

What Is Varnish?

Varnish is a thin, adherent deposit that forms on internal surfaces of lubrication and hydraulic systems. It consists of degraded oil products—oxidized hydrocarbons, depleted additives, and contaminants—that have become insoluble in the base oil. In gas turbines, varnish typically appears as yellow-to-brown films on component surfaces, filters, and in reservoirs.

Causes of Varnish Formation in Gas Turbines

· Oil Degradation: High operating temperatures and pressures accelerate the breakdown of lubricating oil. Over time, this produces insoluble by-products that coalesce into varnish.

· Oxidation: Exposure to oxygen, especially at elevated temperatures, causes the oil to oxidize and generate varnish precursors.

· Contamination: Ingress of water, dust, and metallic particles catalyze oil breakdown and increases varnish formation.

· Additive Depletion: Antioxidants and other additives in turbine oil eventually become depleted, reducing the oil’s ability to resist varnish formation.

Why Is Varnish a Problem?

Varnish poses several risks to gas turbine operation and reliability:

· Sticking Valves: Varnish can cause control and servo valves to stick, leading to unreliable operation or even catastrophic failure.

· Reduced Heat Transfer: Deposits on heat exchangers and bearings impede heat dissipation, causing components to run hotter and degrade faster.

· Poor Lubrication: Varnish coats surfaces, reducing the effectiveness of lubricating oil and increasing wear.

· Filter Plugging: Accumulated varnish can clog fine filters, restrict oil flow, and potentially cause pressure drops or system trips.

Several factors have contributed to increased varnish issues in gas turbine lubricants. Smaller oil lubricant volume, tighter filtration, higher operating temperatures and extending the oil service life. The reduced dwell time leads to a greater chance of entrained air. The air bubbles can lead to micro-dieseling. Micro-dieseling is where an air bubble undergoes rapid compression, i.e., adiabatic compression. This compression leads to elevated temperatures (sometimes greater than 1000 0 C). This results in thermal degradation of the oil. Tighter filtration may cause electrostatic discharge. Higher operating temperatures and extended oil service life increases the oxidation of the oil.

Detection and Monitoring

Early detection of varnish is key to preventing significant issues. Common monitoring techniques include:

· Visual Inspection: Checking for colored films in reservoirs and on component surfaces.

· Membrane Patch Colorimetry (MPC): A laboratory test that measures the quantity of insoluble varnish precursors.

· Linear Sweep Voltammetry: Measures the remaining antioxidants as a relative percentage of the new oil.

· Air Release: Measures the tendency of the lubricant to retain entrained air.

· RPVOT (Rotating Pressurized Vessel Oxidation Test): Measures the time, in minutes, of the oil to oxidize under strenuous conditions.

· FTIR (Fourier Transform Infrared Spectroscopy): Detects oxidation of the fluid as well as contaminants.

· Acid Number: Measures the acidity of the lubricant. The acid number of the fluid slowly increases with increasing service time.

· Particle Counting: Monitoring oil cleanliness to detect increases in fine particulates.

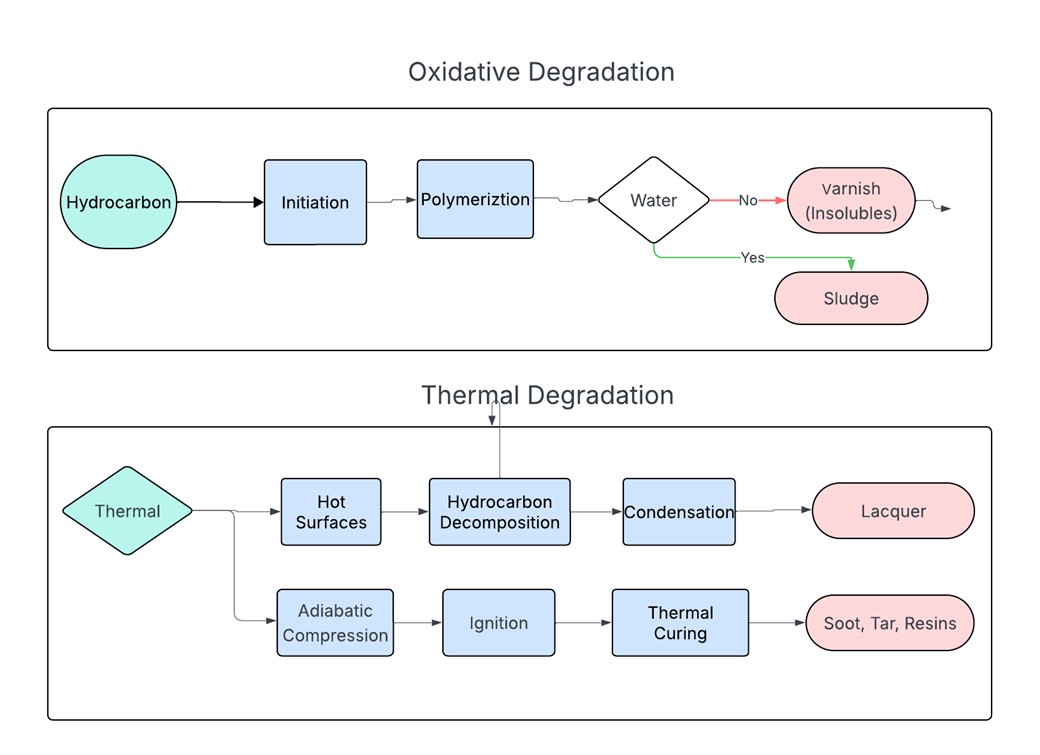

Figure 2 summarizes the degradation pathways of the lubricant degradation, causes, outcomes and key indicators.

Figure 2: The chart shows two primary failure pathways for oil: oxidative degradation and thermal degradation. Oxidative degradation begins with free radical formation which polymerize—if water is absent this tends to form varnish/insoluble deposits, whereas the presence of water promotes sludge formation. Thermal degradation, by contrast, is driven by heat sources (hot surfaces, adiabatic compression, ignition) that decompose hydrocarbons and cause condensation and thermal curing, producing lacquer-like films and heavier combustion products such as soot, tar and resins.

Mitigation and Prevention Strategies

Preventing varnish requires a combination of proactive maintenance and oil management practices:

1. Use High-Quality Lubricants: Select turbine oils with strong antioxidant packages and good thermal stability.

2. Maintain Oil Cleanliness: Regularly filter oil to remove particulates and water that accelerate breakdown.

3. Temperature Management: Avoid excessive oil temperatures to slow oxidation and thermal degradation.

4. Periodic Oil Analysis: Routinely evaluate lubricant health to detect early signs of varnish formation.

5. Varnish Removal Systems: Deploy filtration systems such as electrostatic separators, cellulose depth filters and resin filters specifically designed to remove varnish precursors.

6. Timely Oil Changes: Replace oil before additive packages are fully depleted, based on analysis, not just calendar time.

Conclusion

Varnish is a silent but consequential threat to gas-turbine reliability. By understanding its causes, monitoring the right indicators, and applying proactive mitigation, operators can protect assets, reduce downtime, and extend both turbine and lubricant life. Contact MRT Laboratories to consult with one of our STLE or ICML-certified analysts for program design, troubleshooting, and test panel selection.