Oil analysis ADVANCED TESTING. Answers for you.

The Usefulness of Membrane Patch Colorimetry - ASTM D7843

Answers to questions from the Nov. 13 blog:

‘What am I looking at?’ and ‘Is this a certain oil analysis test?’

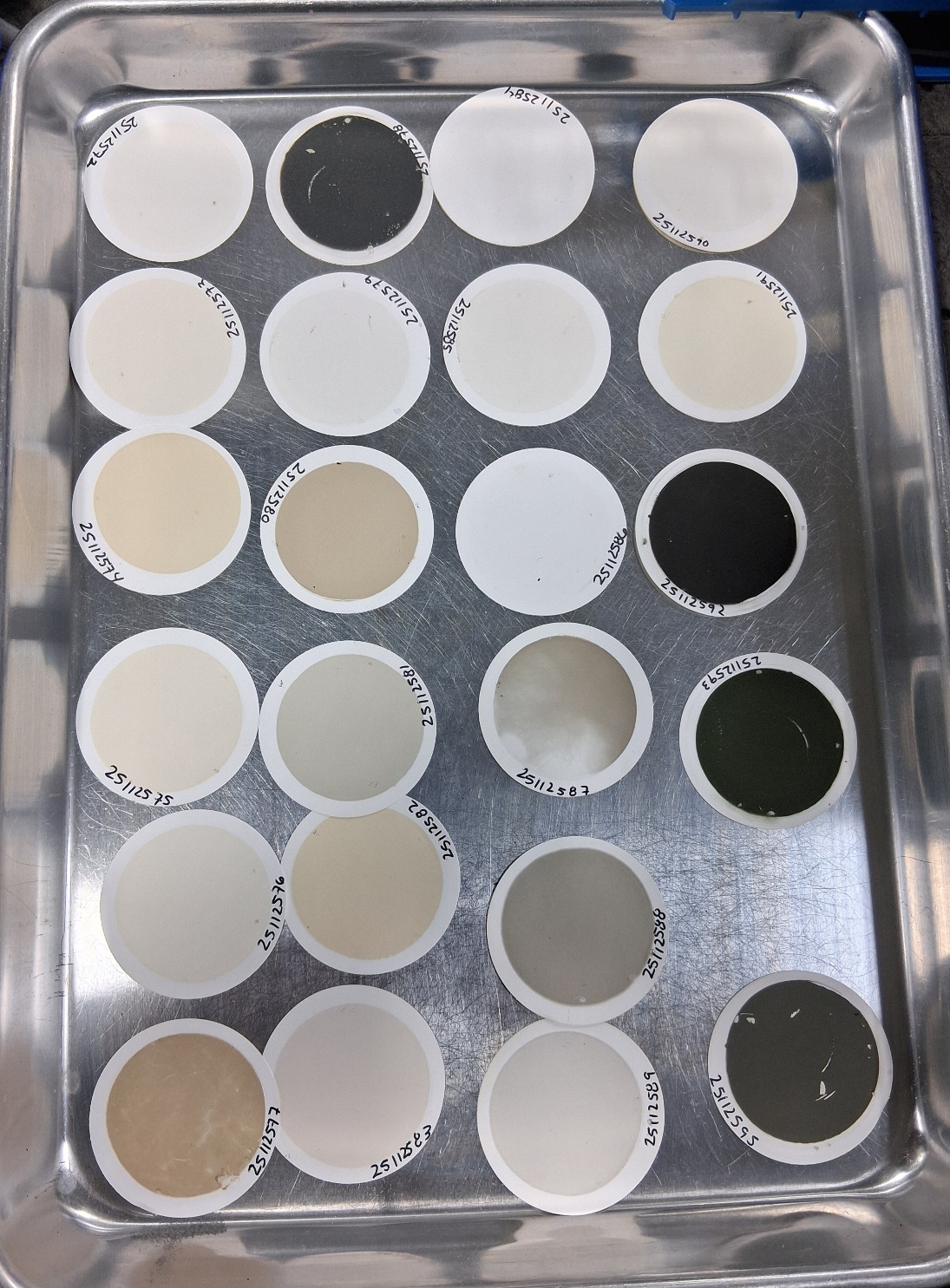

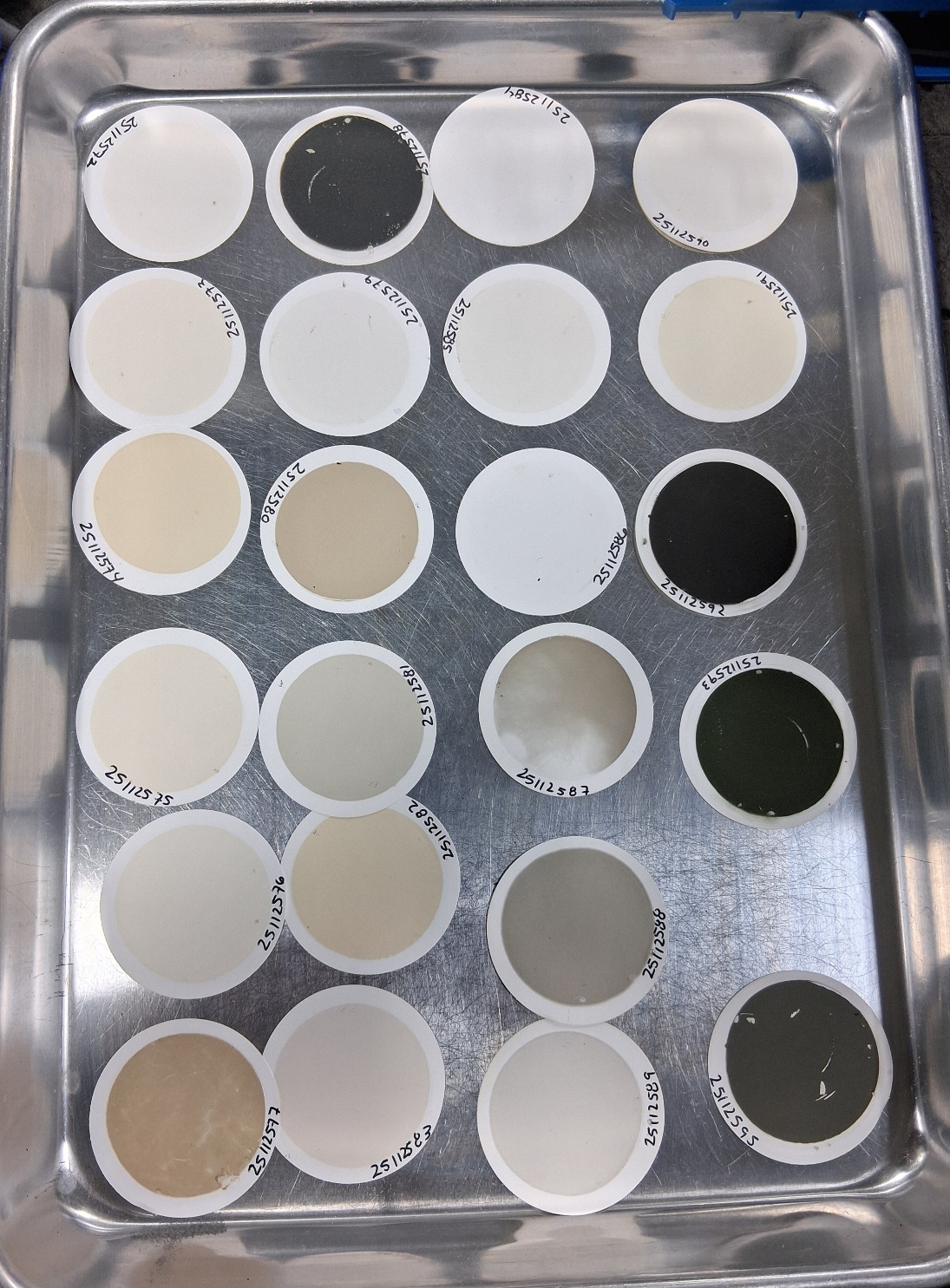

The photo is a tray of membrane filter patches of test results for ASTM D7843 – Membrane Patch Colorimetry, which is a standard test for measuring the varnish potential of in-service lubricants. All of these patches are from different samples from the same MRT customer. The test measures the accumulation of microscopic breakdown products in an oil that are most often caused by oxidation. Breakdown products are attracted to metal surfaces where they accumulate and thicken.

How is this test performed?

The test requires 50 mL of the lubricant which is diluted with the same amount of petroleum ether (or heptane for a common modification). The mixture is filtered through a 0.45 micron patch, rinsed with the solvent and dried. The solvent pulls contaminants out of solution and most used oil mixtures will leave behind a darkened area on the filter patch. The debris left behind is often varnish forming pre-cursors. A ΔE value of the light absorption of the soft contaminants on the patch is calculated using a spectrophotometer and the higher the number, the greater the concentration of these contaminants.

What are the different color patches? and Why are the colors different?

An interesting question. Darker patches indicate a higher risk of varnishing in a unit. The chemistry of a lubricant will influence the color hue. Here are some general trends in colors, and this does not include all possibilities:

- Yellow patch– early-stage oxidation by-products

- Orange / Brown – more advanced oxidation

- Dark brown / Near-black – heavily degraded organics in the sample

Phenol additive depletion will often leave yellow to amber residues on the patch. Amine additive depletion will be darker brown. Soft varnish material on a patch is more likely to be a yellow/orange color patch, and hard varnish will be darker brown to black.

What is a normal test result and what is an abnormal result?

There is some variation in the type of oil being tested, but for most turbine, circulating, and hydraulic oils a NORMAL test result of MPC ΔE value of < 15. The scale is from 0 to 100. For most oils the initial noticeable level of contamination is a ΔE value of 15. At a ΔE = 35 a yellow or red flag is raised and at a ΔE >= 50 the concentration level is considered SEVERE.

Why so many patches?

We encourage customers to test as many applicable units as possible at the same time, so everyone can compare and rank the results together, and triage varnish remediation in a systematic fashion.

How do I use this information?

Trending an increase in this test result is very important and a normal test frequency is once every six months unit a yellow or red flag is raised and then the test frequency increases. There is more to interpreting varnish potential test results than just the MPC ΔE number as a stand-alone. Soot, or other thick contaminants in the oil can also accumulate on a membrane patch and elevate the ΔE light absorbance measurement and is not necessarily a varnish forming material. And lastly, just because an MPC ΔE is elevated does not mean that the soft contaminants are falling out of solution and causing varnish. Certain oils, often synthetic oils, are very solvent and can hold contaminants in solution even through extended periods of adverse conditions. An elevated MPC warrants an investigation for signs of varnishing but does not indicate with certainty that varnishing has already occurred.